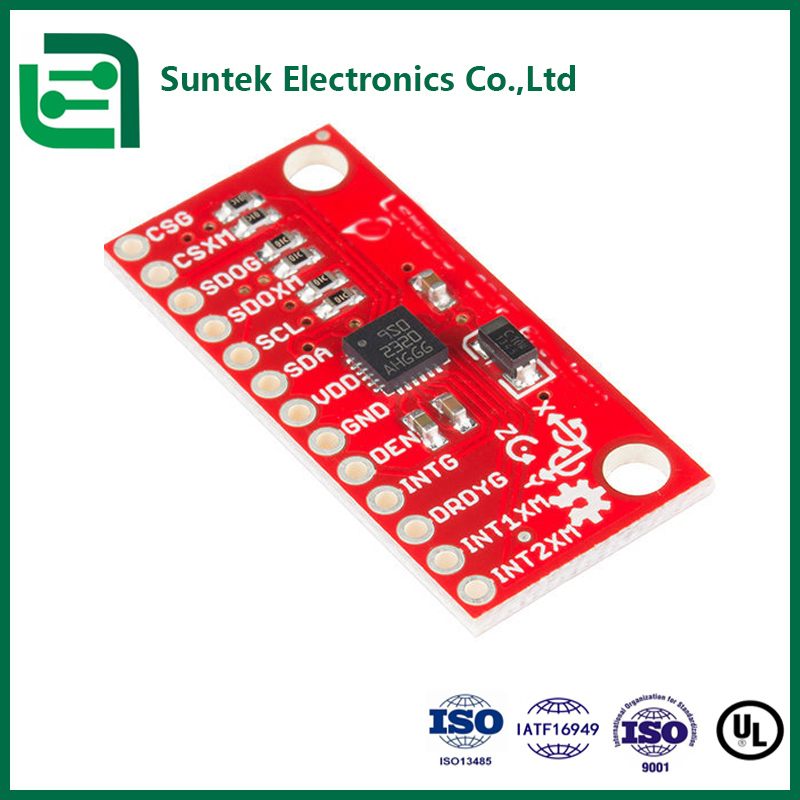

Prototype SMT THT PCB Assembly for FR4 Printed Circuit Board Lead Free HASL RoHS Standard

Suntek Group is a contract supplier in EMS field providing one-stop solutions for PCB/FPC assembly, cable assembly, and box-build assembly. With facilities in Hunan Province, China and Kandal Province, Cambodia, we deliver qualified products with competitive pricing worldwide.

Certified with ISO9001:2015, ISO13485:2016, IATF 16949:2016 and UL E476377, we transform your Gerber files and BOM into finished products. We also offer reverse-engineering services from physical samples and joint-design services for new product development.

PCB Assembly Capabilities

| Item | Parameter |

|---|

| Board Type | Rigid PCB, Flexible PCB, metal core PCB, Rigid-Flex PCB |

| Board Shape | Rectangular, Circular and any irregular Shapes |

| Max Size | 400mm * 1200mm |

| Min Package | 0201 |

| Fine Pitch Parts | 0.25mm |

| BGA Package | Acceptable |

| DIP Capacity | DIP lines and AI assembly line |

| Parts Sourcing | All by Suntek or partial consigned by customer |

| Parts Package | Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk |

| Testing | Visual inspection, AOI, X-RAY, Functional Testing |

| Types of Solder | Lead or Lead-free (RoHS Compliant) assembly |

| Assembly Option | Surface mount (SMT), Through-hole (DIP), Mixed technology (SMT & Thru-hole) |

| Stencils | Laser cut stainless steel stencils, step-down stencil |

| File Formats | Bill of Materials, PCB (Gerber Files), Pick-N-Place File (XYRS) |

| Quality Grade | IPC-A-610 Class 2/Class 3 |

Product Features

High-Quality FR4 Substrates

Utilizes FR4 base material with high Tg values for excellent thermal resistance, mechanical strength, and electrical performance. Widely used in industrial control, automotive electronics, consumer electronics, and communication equipment.

Lead-Free Eco-Friendly Processes

Employs lead-free HASL technology compliant with RoHS standards, using lead-free reflow and wave soldering for robust, consistent solder joints.

High-Precision Assembly Capabilities

Handles components as small as 0402 and 0201 packages (2mm x 1mm) and precision ICs like QFP and BGA, adhering to IPC-A-610 Class standards.

Stringent Quality Control

Implements comprehensive inspection methods including AOI, X-Ray, SPI, and FCT. ISO 9001 certified for batch consistency and traceability.

Support for Diverse Technical Requirements

Offers double-sided DIP insertion, selective wave soldering, and flexible customization for both rapid prototyping and large-scale production.

Our Services

- PCB/FPC fabrication

- Components sourcing

- PCB/FPC assembly

- Custom cable/harness assembly

- Box build assembly

- SMT, THT, BGA, 0201 Chips assembly

- AOI, X-Ray, ICT, FT, Burn-in testing

- Conformal coating or gluing

- High-mix, small to medium volume production

EMS Advantages

- Strict product liability following IPC-A-610 standard

- Fluent English-speaking teams

- PDCA management tool implementation

- 100% E-test and visual inspection at all quality checkpoints

- 100% AOI inspection including X-ray, 3D microscope and ICT

- High-voltage test and impedance control test

- ISO9001, ISO13485, IATF16949 and UL certified

- No minimum order quantity requirements

- Specialization in low to medium volume production

- Quick and reliable delivery

Why Choose Suntek?

As an experienced manufacturer, Suntek provides comprehensive services from PCB manufacturing to assembly, helping global customers save time and money while maintaining high quality standards.

Instant Quote

Receive quotes within 24-48 hours with positive feedback on all project specifications.

Strong Team

Our professional engineers provide technical support throughout the entire process from PCB design to turnkey assembly.

Automatic Equipment

Advanced automation improves efficiency and cost-effectiveness, delivering high-quality boards at competitive prices.

After Sales Service

We track all orders with customer service representatives available for instant updates throughout the process.

Our Support

We ensure cost transparency with BOM cost breakdown sharing and global component sourcing. Our structured processes include:

- Customer service procedure

- RMA procedure

- 8D reports

- PDCA (Plan-Do-Check-Action) in customer service

We respond to complaints and queries within 24 hours through weekly reports, customer support team reviews, and satisfaction questionnaires.

After-sales Services

- 1-year guarantee period for all products

- Free-of-charge repairs

- Quick compensation parts replacement

FAQ

Q1: What files do you use in PCB fabrication?

A1: Gerber, PCB, and Auto CAD files.

Q2: How do you ensure quality?

A2: 100% E-testing for PCBs, with 100% AOI, ICT, FT, visual checking, and X-ray for BGA components.

Q3: Can we visit your company?

A3: Yes, we welcome visits to our facility in Xingsha Industrial Park, Changsha, Hunan province, China.

Q4: What is the lead time?

A4: Samples take 3-5 working days, batch production 7-10 working days based on files and quantity. PCB assembly takes 15-20 working days.

Q5: Will you keep our information confidential?

A5: Absolutely. Protecting customer designs is fundamental. NDAs can be signed at any time.

Q6: How to work with you?

A6:

- Email us your PCB layout file and BOM list

- We confirm within 12 hours and provide quotes in 3-5 days

- Upon your confirmation of price, order, and payment terms

- We proceed with the order

With advanced equipment, professional teams, and strict quality control, our products serve industrial control, automotive, telecommunications, medical equipment, and consumer electronics sectors.

Factory Pictures

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!